Case Study: Transforming Scaffold Inspections at Enigma Industrial Services

In high-stakes industrial environments like chemical and water treatment plants, scaffold inspection and handover processes demand precision, reliability, and speed. At Enigma Industrial Services, these demands are met and exceeded thanks to the adoption of CADS’ SMART Inspector and SMART Handover solutions.

One of the standout champions of the SMART platform is Darren Olsson, an experienced scaffolder with over three decades in the field. Based at their client’s site in West Yorkshire, Darren has personally completed more than 85,000 scaffold handovers and inspections using SMART tools—making him the most prolific user across our customer base.

We recently spoke with Darren to understand how SMART Inspector and SMART Handover have impacted his workflow, and why he would confidently recommend the system to others in the industry.

About Darren Olsson working on the Client’s Site

Darren has worked in the scaffolding industry for an impressive 33 years, with the last 12 spent at this production facility. For the past decade, he has held the role of Scaffold Inspector at this critical site, which operates 365 days a year.

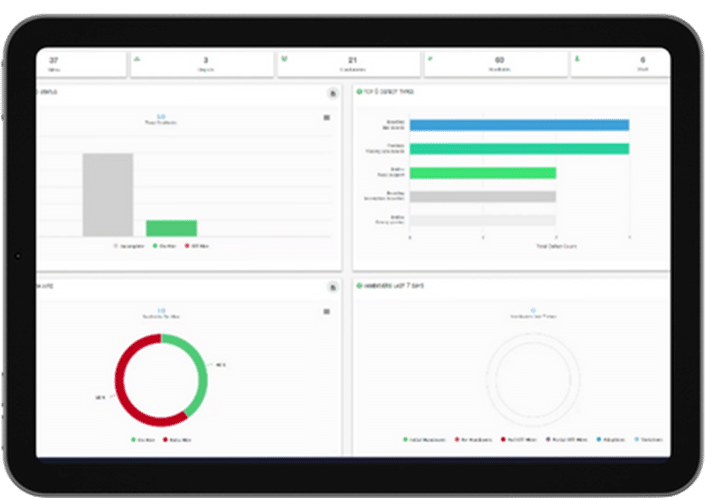

Since adopting SMART Manager on the site, they have completed over 130,000 inspections and handovers with Darren personally completing over 85,000 of those! The site’s scale and complexity require a rigorous, well-documented approach to scaffold management. Prior to SMART, Darren and his team relied on traditional scaff tags and F91 paper records—manual systems that posed logistical challenges in such a demanding environment.

Transitioning from Paper to SMART

“Before SMART Scaff, we were using a Scaff tag system and F91 paper records. Every inspection required physically signing off white cards weekly, which was incredibly time-consuming,” Darren explains.

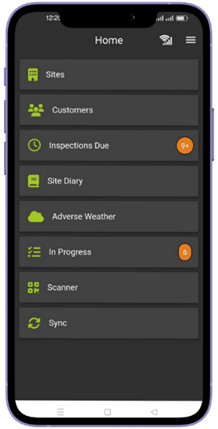

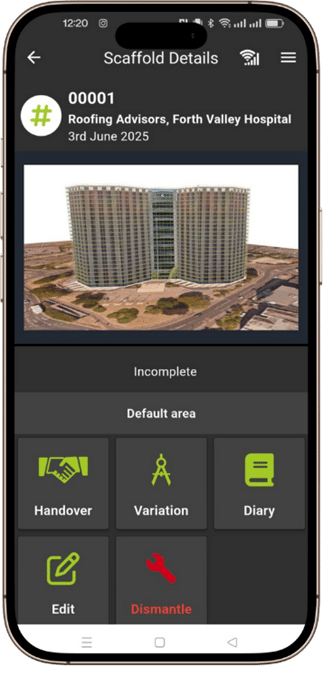

With SMART Inspector and SMART Handover, Darren now carries out his inspections digitally, with updates synced automatically to the system. “There’s a huge time saving,” he notes. “Instead of manually tracking everything, the software records and uploads my entire day’s work in real time.”

Key Benefits at a Glance

1. Improved Visibility and Accuracy

Each scaffold on the client’s site is assigned a unique number and mapped to a specific area. With SMART, locating and updating scaffold records is seamless. The system supports multi-tagging, allowing complex scaffolds with multiple ladder access points to be properly tracked and managed.

“The red and green dot system is brilliant. I can instantly tell if a scaffold has been missed or inspected—there’s no guesswork,” Darren adds.

2. Enhanced Efficiency in Harsh Environments

For Darren, one of the standout differences has been weather resilience. “Not having to carry paper copies of F91 forms in bad weather is a game-changer. Everything I need is on the device—dry, safe, and accessible.”

3. More Time on Site, Less on Paperwork

The time saved using SMART tools allows Darren to focus more on-site safety and inspection quality. “I get more done on site because I’m not bogged down by admin. That alone makes a huge difference.”

4. Excellent Customer Support

Beyond the technology, Darren praises the customer support from the SMART Scaff team. “Support has been excellent. Whenever I’ve needed help, it’s been there.”

The Verdict: Highly Recommended

After 85,000+ inspections and nearly a decade of hands-on experience with SMART Scaffolder, Darren’s recommendation carries weight:

“I would highly recommend SMART Scaff software. It’s user-friendly, reliable, and saves a huge amount of time. It’s changed the way I work—and for the better.”

To find out more about SMART Manager, Inspector or Handover speak to the SMART Scaffolder Team today

You can Learn more about Enigma Industrial Services here

Recent posts

Keeping Your Scaffolds Safe in Unpredictable Weather

January 2026 Project of the Month: JR Scaffold Services Ltd.

Why Daily Vehicle Checks Matter: Staying Compliant with the Road Traffic Act 1991

Digital Detox for Scaffolders: Start the Year with a Cleaner, Faster SMART Scaffolder Setup

December’s Project of the Month: Hard Rock Scaffolding at Dutch Village.

November’s Project of the Month: WB Scaffolding at Smash Burger, Brighton.

Why Accurate Incident Reporting Matters: Staying Compliant with RIDDOR 2013

Why Tie Testing Matters: Staying Compliant with NASC TG4:25

October’s Project of the Month: Amphibian Scaffolding at Chartwell Hockley Industrial Centre

Why Harness Inspections Matter: Staying Compliant with NASC SG16:23

September’s Project of the Month: OAK Scaffolding Limited: Caterham School

Why the Scaffolding Industry Must Embrace Technology

August’s Project of the Month: SAY Access Limited at Appleton Academy

Sustainability Through Innovation in Construction:

Project of the Month: July – JRS Scaffolding

Bridging the Skills Gap in Scaffolding: How Technology Can Attract the Next Generation

Project of the Month – June – Blenheim Palace

SMART Scaffolder’s 20th Anniversary event

Engineering Smart Solutions in Tight Spaces: PJ Slater’s Stamford & Rutland Hospital Project

Why Every Scaffolding Company Needs a Strong GRC Framework –

Sonic Scaffolding 2000 ltd is driving Project Success with SMART Estimator’s Accurate 3D Planning

Infiniti Scaffolding LTD: Boosting Efficiency with SMART Inspector: A Success Story

Building Safer Heights: Tackling Falls with Better Scaffolding Practices

The Future of Scaffolding Workflow software

SCA Group’s Centenary Quays Project: Project of the Month January 2025

Battling the Elements: How to Keep Your Scaffolds Safe in Adverse Weather

Navigating Scaffold Safety: The Critical Importance of Handover Certificates